Soft robotic device using elastomeric pneumatic actuators

Across the globe, numerous preterm infants encounter challenges with suction-swallowing during their inaugural year, stemming from malformations, neurological complexities, and transient irregularities, in Lima, Peru, a substantial number of newborns face issues with suction-swallowing functionality. Dysregulated suckling behaviors in premature neonates result in disruptions not solely confined to breastfeeding but also impacting their orofacial motor proficiency, frequently culminating in nipple confusion syndrome.

One approach for rehabilitating oral-motor sensory issues in infants with difficulties in suction-swallowing involves a therapeutic regimen of exercises, including circular compression within the masseter muscle, thereby inducing continual vibration and rotation in each cycle. To simulate these movements, a device needs to fulfill specific design criteria, being compact, lightweight, pliable, and user-friendly.

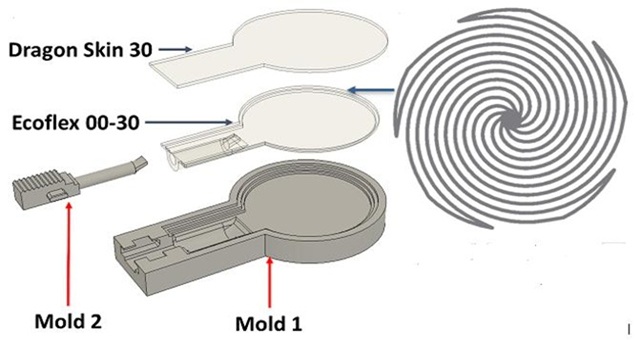

Consequently, we designed a device known as the Normal SPA (exerting a normal force), comprised of two layers of silicone materials. The bottom layer, made of Ecoflex (00-30, Smooth-On, Inc.), was paired with a top layer of Dragon Skin (30, Smooth-On, Inc.), possessing a significantly higher Young's modulus. To prioritize deformation in the Ecoflex layer, we introduced a PET foil, flexible and inextensible, between the Dragon Skin layer and the inflated Ecoflex layer. This strategic implementation notably constrained movement in the Dragon Skin layer, promoting motion predominantly in one direction.

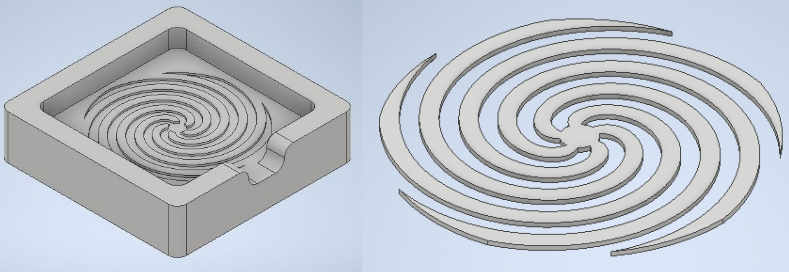

To achieve rotational movement in the neonate's facial muscle, we integrated a 3D flexible spiral-shaped structure composed of TPU Flex into the bottom Ecoflex layer of the Normal SPA. This configuration allowed for a singular air input to generate both rotational and perpendicular movement.

Consequently, an SP SPA was constructed, featuring a 2mm thick Dragon Skin layer, a PET foil, an intermediary Ecoflex layer measuring 0.75mm, a 0.4mm thick flexible spiral, and an Ecoflex layer approximately 1mm thick.

Figure 1.Mechanical Ventilator Prototype

Figure 2. Negative and positive 3D CAD models for the spiral part.